How Did A Printing Press Work

The invention of the printing press marked a revolutionary moment in human history, forever changing the way information was disseminated and accessed. This simple yet powerful machine, designed to automate the printing process, played a pivotal role in the spread of knowledge, the evolution of the book industry, and the cultural and intellectual advancements of societies worldwide.

The Mechanical Marvel: An Overview of the Printing Press

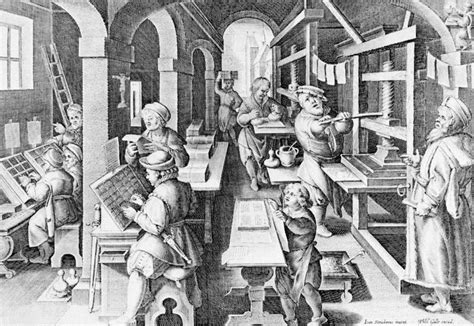

The printing press, a mechanical device for applying pressure to an inked surface resting upon a print medium, such as paper or cloth, allowing for the transfer of an image, is an intricate and ingenious piece of machinery. Its design and operation are rooted in a combination of mechanical principles and innovative engineering.

At its core, the printing press employs a system of levers and screws to apply immense pressure to a printing surface, which can be a metal plate, a wooden block, or a modern-day printing plate. This pressure transfers the inked image onto the medium, creating a printed impression. The process involves several key components, each playing a critical role in the overall printing mechanism.

Key Components of a Printing Press

The printing press consists of several essential parts, including the frame, which provides the structural support for the entire mechanism; the bed, a flat surface upon which the printing plate is placed; the platen, a flat piece of metal that applies pressure to the paper against the printing plate; and the ink distribution system, which ensures an even and controlled application of ink onto the printing surface.

Additionally, the printing press features a system of rollers and gears for smooth and precise movement of the printing plate and paper. These mechanical elements work in harmony to facilitate the efficient and accurate printing process.

| Component | Function |

|---|---|

| Frame | Provides structural support |

| Bed | Holds the printing plate |

| Platen | Applies pressure for printing |

| Ink Distribution System | Ensures even ink application |

| Rollers and Gears | Facilitates movement and precision |

The Printing Process: A Step-by-Step Journey

The printing process is a meticulous and well-orchestrated sequence of steps, each contributing to the final printed product. From the preparation of the printing surface to the distribution of the printed materials, every stage is critical to the overall success of the printing endeavor.

Step 1: Preparation of the Printing Surface

The first step in the printing process involves preparing the printing surface, whether it’s a metal plate, a wooden block, or a modern printing plate. This preparation typically involves a meticulous cleaning process to ensure the surface is free of any debris or contaminants that could affect the quality of the printed impression.

Once cleaned, the printing surface is then inked. This process requires precise application of ink to ensure an even and consistent coverage. The ink is typically applied using a roller or a similar mechanism, ensuring a smooth and uniform layer of ink is transferred onto the printing surface.

Step 2: Loading the Paper

With the printing surface prepared, the next step involves loading the paper onto the printing press. This is a critical stage as it requires precise alignment of the paper with the printing surface to ensure accurate and consistent printing. The paper is typically fed into the press using a feeder mechanism, which ensures a steady and controlled supply of paper for printing.

Step 3: Printing

The heart of the printing process lies in the actual printing stage. Here, the printing press applies pressure to the inked printing surface, transferring the image onto the paper. This is achieved through a carefully calibrated system of levers and screws, which apply immense pressure to ensure a crisp and clear printed impression.

The printing process is often repeated multiple times to ensure a high-quality print. Each print is carefully inspected to ensure consistency and accuracy. Any deviations or errors are addressed through adjustments to the printing press or the printing surface.

Step 4: Drying and Finishing

Once the printing process is complete, the printed materials are subjected to a drying process to ensure the ink sets properly. This is a critical stage, as it prevents smudging or smearing of the printed impression. The drying process can vary depending on the type of ink and printing medium used.

After drying, the printed materials may undergo additional finishing processes, such as trimming, binding, or coating, to enhance their appearance and durability. These finishing touches contribute to the overall quality and presentation of the printed materials.

The Impact of the Printing Press: A Historical Perspective

The invention and widespread adoption of the printing press had a profound impact on human history, shaping the course of cultural, intellectual, and societal development in ways that are still felt today. Its influence extended far beyond the realm of printing, permeating every aspect of human life and society.

Spreading Knowledge and Education

One of the most significant impacts of the printing press was its role in the dissemination of knowledge. Prior to the invention of the press, books and written materials were rare and expensive, often accessible only to the privileged few. The printing press revolutionized this by making books and other printed materials more affordable and widely available, thus democratizing access to knowledge.

With the printing press, it became possible to produce multiple copies of a book or document quickly and efficiently. This led to a surge in literacy rates as more people had access to books and educational materials. The spread of knowledge and ideas through printed materials played a crucial role in the Renaissance and the Age of Enlightenment, fostering intellectual curiosity and advancement.

Advancing the Book Industry

The printing press also had a profound impact on the book industry. Prior to its invention, books were painstakingly produced by hand, a process that was time-consuming and labor-intensive. The printing press revolutionized book production, making it faster, more efficient, and more cost-effective.

With the printing press, it became possible to produce large quantities of books in a relatively short period. This led to a flourishing of the book industry, with an explosion of titles on various subjects. The availability of a wide range of books encouraged reading, research, and the exchange of ideas, contributing to the growth and development of various fields of knowledge.

Cultural and Social Impact

The printing press had a profound cultural and social impact as well. It played a pivotal role in the spread of ideas and the formation of public opinion. With the availability of printed materials, people could access a wide range of perspectives and ideas, fostering critical thinking and debate.

The printing press also contributed to the development of a shared cultural identity. Printed materials, such as newspapers and books, helped to shape and reflect the values, beliefs, and aspirations of societies. The widespread distribution of printed materials facilitated the spread of cultural norms and practices, contributing to a sense of unity and common identity.

The Evolution of Printing Technology: A Modern Perspective

While the printing press revolutionized printing and information dissemination, the world of printing has continued to evolve and advance, driven by technological innovations and changing societal needs. Today, the printing industry encompasses a wide range of technologies and processes, each tailored to meet specific printing requirements.

Offset Printing

Offset printing is a widely used printing technique that employs a system of plates, blankets, and rollers to transfer ink onto paper or other materials. This process involves the use of a printing plate, which is etched with the desired image or text. The plate is then inked, and the image is transferred onto a rubber blanket, which in turn transfers the image onto the printing surface.

Offset printing is known for its high-quality prints and is often used for printing large quantities of materials, such as magazines, brochures, and books. Its ability to produce consistent and high-quality prints makes it a popular choice for commercial printing.

Digital Printing

Digital printing is a modern printing technique that utilizes digital files and digital printing machines to produce printed materials. Unlike traditional printing methods, which require the preparation of printing plates, digital printing uses computer-generated images and text, which are sent directly to the printing machine.

Digital printing offers several advantages, including flexibility, speed, and cost-effectiveness. It is ideal for small print runs, personalized printing, and on-demand printing. With digital printing, it is possible to produce high-quality prints with minimal setup time and costs, making it a popular choice for short-run printing projects.

3D Printing

3D printing, or additive manufacturing, is a cutting-edge printing technology that involves the creation of three-dimensional objects through a layer-by-layer printing process. This technology has revolutionized manufacturing and design, offering unprecedented flexibility and precision in the creation of physical objects.

3D printing works by reading a digital file, which contains the design of the object to be printed. The printing machine then deposits layers of material, often plastic or metal, to build the object from the ground up. This technology has applications in various industries, including aerospace, automotive, healthcare, and consumer goods, offering new possibilities for product design and manufacturing.

Conclusion: The Enduring Legacy of the Printing Press

The printing press, with its mechanical ingenuity and transformative impact, remains an enduring testament to human innovation and ingenuity. Its invention and widespread adoption revolutionized the way information was disseminated, paving the way for the spread of knowledge, the advancement of the book industry, and the cultural and intellectual development of societies worldwide.

While the world of printing has evolved and advanced with new technologies, the fundamental principles and impact of the printing press remain. Its legacy continues to inspire and shape the printing industry, driving it forward with new possibilities and innovations. The printing press, in its various forms and iterations, continues to play a vital role in our lives, facilitating the exchange of ideas, the sharing of knowledge, and the advancement of human civilization.

What is the significance of the printing press in history?

+

The printing press revolutionized information dissemination, making books and knowledge more accessible. This had a profound impact on education, the book industry, and cultural development, fostering intellectual curiosity and societal progress.

How has the printing press evolved over time?

+

The printing press has evolved from a mechanical device to modern digital and 3D printing technologies. These advancements have increased efficiency, flexibility, and precision, shaping the printing industry and its applications.

What are the key components of a printing press?

+

Key components include the frame, bed, platen, ink distribution system, and rollers/gears. These elements work together to apply pressure and transfer ink, creating printed impressions.