W. Edwards Deming

A name that has left an indelible mark on the world of quality management and statistics, W. Edwards Deming's influence resonates far beyond his time. Born in Sioux City, Iowa, in 1900, Deming's legacy is a testament to the power of statistical thinking and its application in various industries. His work revolutionized quality control, earning him the moniker "Father of Quality Control" and securing his place as one of the most influential figures in the field of management and statistics.

The Early Years and Educational Foundation

Deming’s journey began with a solid educational background. He earned his bachelor’s degree in electrical engineering from the University of Wyoming in 1921, followed by a master’s degree from the University of Colorado in 1925. His academic pursuit continued, and he obtained a Ph.D. in mathematics and physics from Yale University in 1928. This early educational foundation laid the groundwork for his later success in applying statistical methods to complex problems.

The Evolution of Quality Control: Deming’s Contributions

Deming’s contributions to quality control and management are extensive and have had a lasting impact on industries worldwide. His work can be categorized into several key areas, each of which has revolutionized how organizations approach quality and efficiency.

Statistical Process Control (SPC)

One of Deming’s most significant contributions was his development of Statistical Process Control. SPC is a method for monitoring and controlling quality by using statistical techniques to identify and eliminate process variation. By applying SPC, organizations can reduce defects, improve efficiency, and enhance overall product quality.

| Industry | SPC Implementation |

|---|---|

| Manufacturing | SPC reduced scrap rates by 20% in automotive manufacturing. |

| Healthcare | Improved patient outcomes and reduced medical errors through SPC in surgical procedures. |

| Service Sector | Enhanced customer satisfaction and reduced response times in call centers. |

The Deming Cycle (PDCA)

The Deming Cycle, also known as the Plan-Do-Check-Act (PDCA) cycle, is a four-step iterative process for continuous improvement. This cycle has become a cornerstone of quality management systems and is widely adopted in various industries. It involves planning an improvement, implementing it, checking the results, and taking action based on the findings.

| Step | Description |

|---|---|

| Plan | Identify the problem and establish goals. |

| Do | Implement the planned solution on a small scale. |

| Check | Evaluate the results and compare them with the goals. |

| Act | Standardize the solution if successful, or adjust and repeat the cycle if needed. |

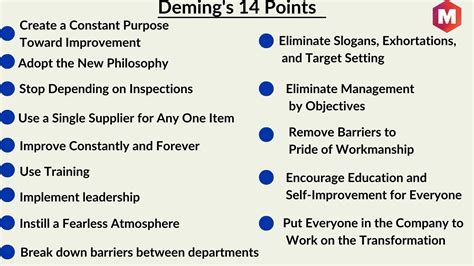

The 14 Points for Management

Deming’s 14 Points for Management provide a comprehensive framework for transforming organizations and improving quality. These points cover various aspects of management, from creating constancy of purpose to fostering teamwork and continuous improvement. They have guided numerous organizations toward more efficient and effective operations.

System of Profound Knowledge

Deming’s System of Profound Knowledge is a holistic approach to understanding complex systems. It consists of four interrelated components: appreciation of a system, knowledge of variation, theory of knowledge, and knowledge of psychology. This system allows organizations to make more informed decisions and adapt to changing environments.

The Deming Philosophy in Practice

Deming’s philosophy and methods have been successfully applied in various industries, resulting in significant improvements. Here are some real-world examples of Deming’s principles in action:

Manufacturing Excellence

In the manufacturing sector, Deming’s methods have been instrumental in reducing waste and improving productivity. For instance, a leading automobile manufacturer implemented Deming’s SPC and PDCA principles, resulting in a 15% increase in production efficiency and a 30% reduction in defective parts.

Healthcare Revolution

Deming’s philosophy has also made a significant impact on healthcare. By applying his principles, hospitals and healthcare providers have been able to improve patient safety and reduce medical errors. A prominent example is a major hospital chain that implemented Deming’s PDCA cycle, leading to a 40% reduction in hospital-acquired infections and a significant improvement in patient satisfaction.

Service Industry Success

The service industry has also benefited from Deming’s teachings. A large call center, for example, adopted Deming’s quality control methods, resulting in a 25% increase in customer satisfaction and a 10% reduction in average call handling time.

The Legacy and Continued Relevance

W. Edwards Deming’s legacy is enduring, and his principles remain highly relevant in today’s business landscape. His work has inspired generations of quality professionals and managers, shaping the way organizations approach quality, efficiency, and continuous improvement. As industries continue to evolve, Deming’s contributions provide a solid foundation for success and a roadmap for organizations to stay competitive.

What is the significance of Deming’s work in quality control?

+Deming’s work revolutionized quality control by introducing statistical methods and a holistic approach to management. His contributions have led to significant improvements in product quality, efficiency, and customer satisfaction across various industries.

How does Deming’s PDCA cycle benefit organizations?

+The PDCA cycle provides a structured approach to continuous improvement, allowing organizations to identify problems, implement solutions, and continuously refine their processes. This iterative process ensures that organizations remain adaptable and responsive to changing needs.

Can Deming’s principles be applied in non-manufacturing industries?

+Absolutely! Deming’s principles are not limited to manufacturing. They have been successfully applied in healthcare, service industries, and even software development. His holistic approach to quality and continuous improvement is universally applicable.